Laying on wet sand with cement

The slabs are laid on a base of sand mixed with cement. This technique guarantees the slabs long term stability and their vehicle accessibility. It also allows to lay the slabs straight on the floor screed avoiding the high costs of the levelling screed arrangements. Expansion joints are necessary and joints must be filled with cementitious grout. It is recommended to lay with a 2% slope to avoid water accumulation.

DRIVE-OVER

Drive-over for slabs with

2, 3 and 6 cm (0.8", 1.2" and 2.4") thickness

Installation

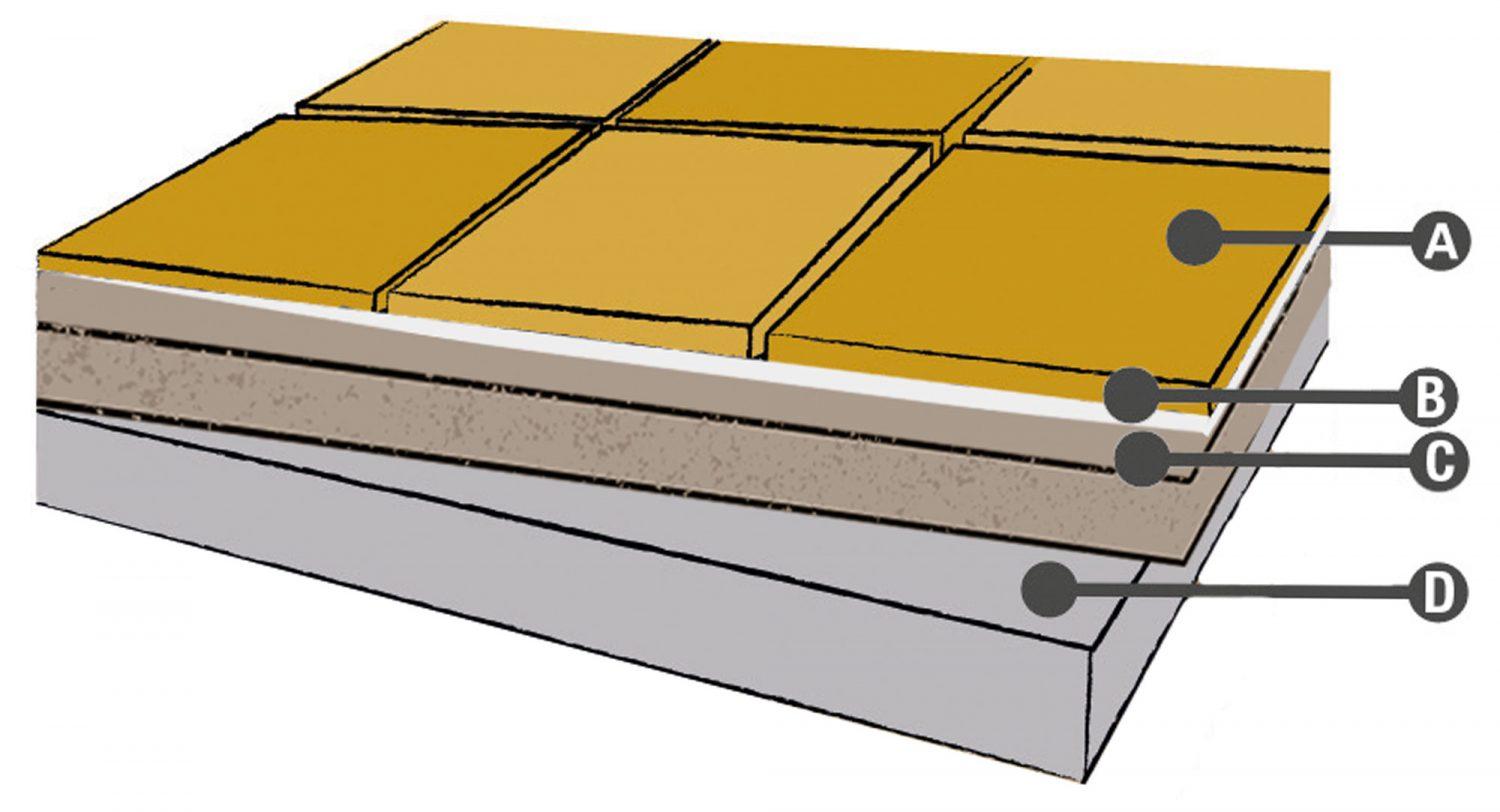

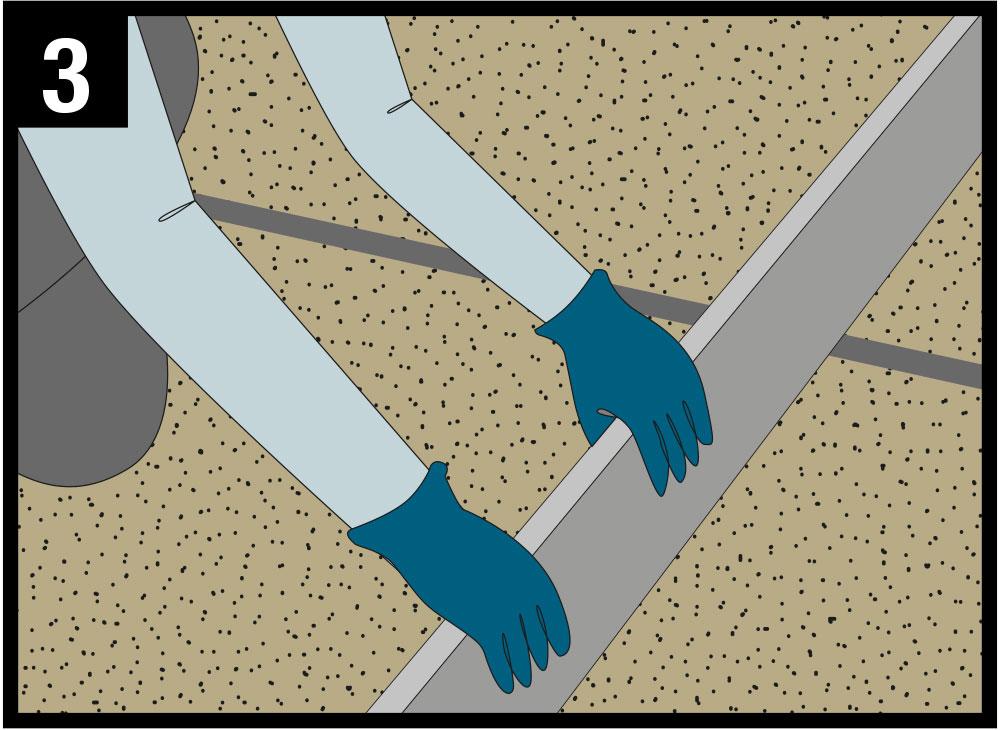

Example of laying on ground

- A) Slab

- B) Adhesive for sintered stone

- C) Sand with cement levelling screed

- D) Structural screed

The proposed diagrams and indications are purely indicative of the type of application: please refer to the specific regulations in force in your country in order to lay the floor to the highest technical standards. It is recommended to lay with a 2% slope to avoid water accumulation.

ADVANTAGES

- Maximum stability over time

- Ideal for driveways

- Ideal for intense pedestrian circulation

DESTINATIONS

- Driveways

- Pool sides

- Terraces

- Car parking

- Residential areas

- Commercial areas

- Outdoor stairs

- Garage ramps

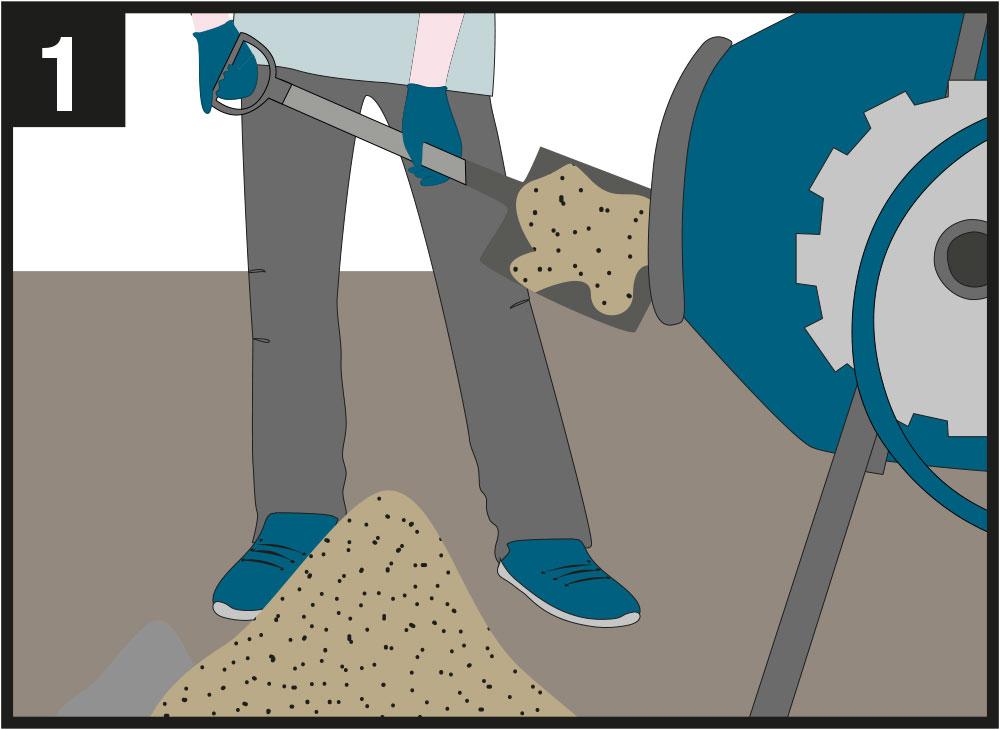

Instructions:

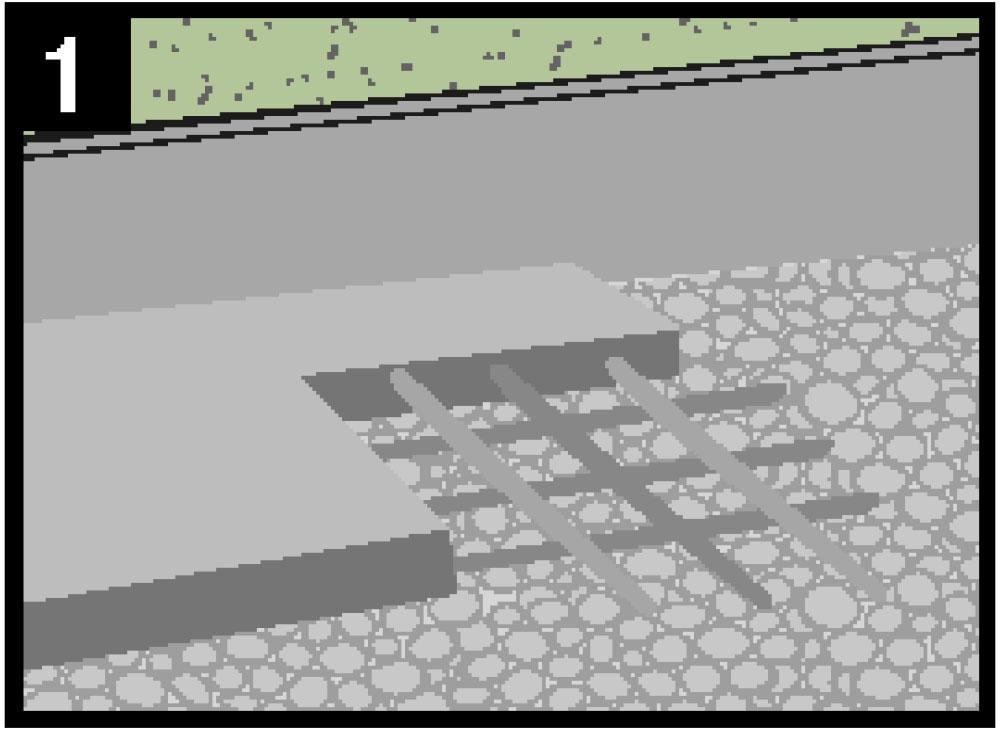

1) Prepare the mixture of sand and cement in the concrete mixer, two parts of cement by weight per ten parts of sand. Cement and water in equal parts.

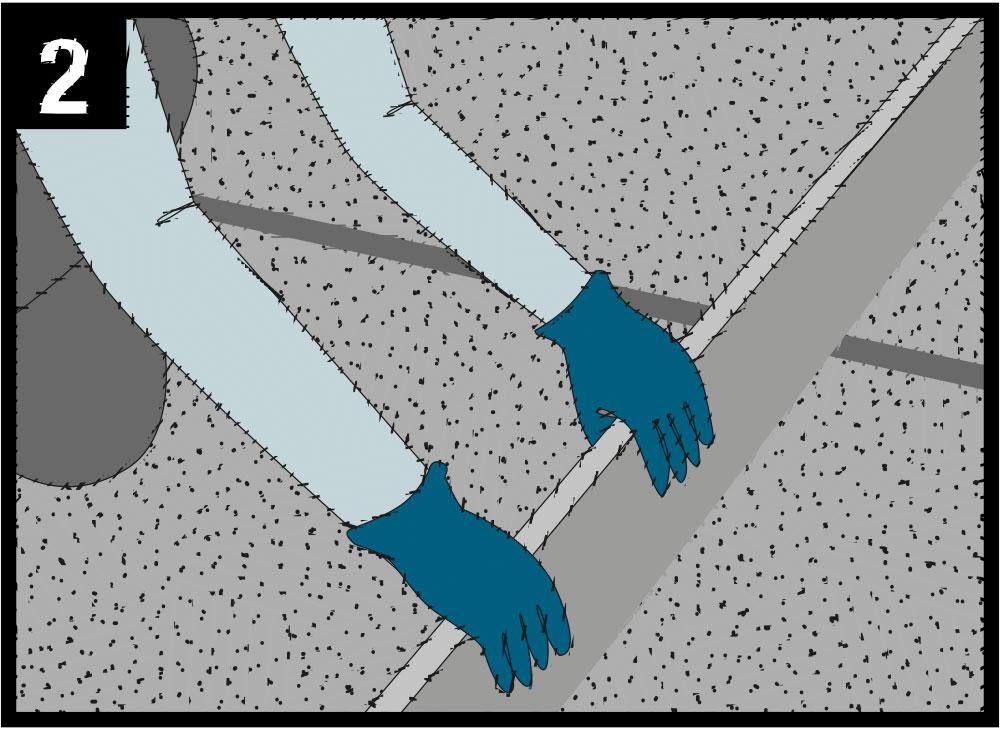

2) Lay the mixture over the existing screed and level it guaranteeing a slope of at least 2%. The layer thickness must be between 5 to 7 cm (2”- 3”) to guarantee drive-over.

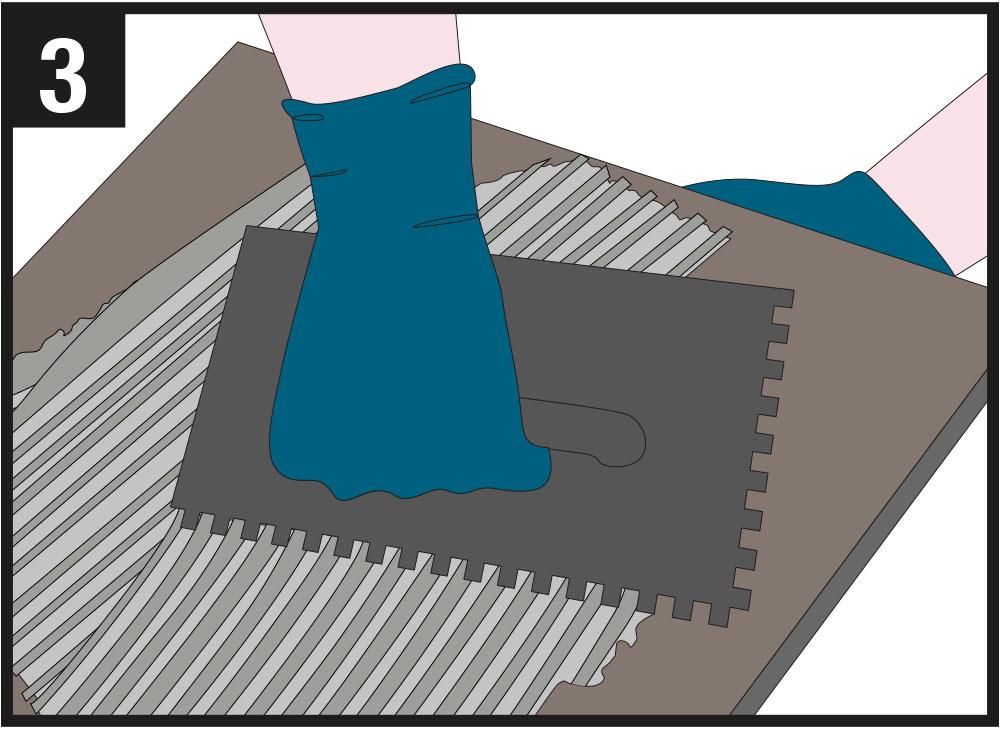

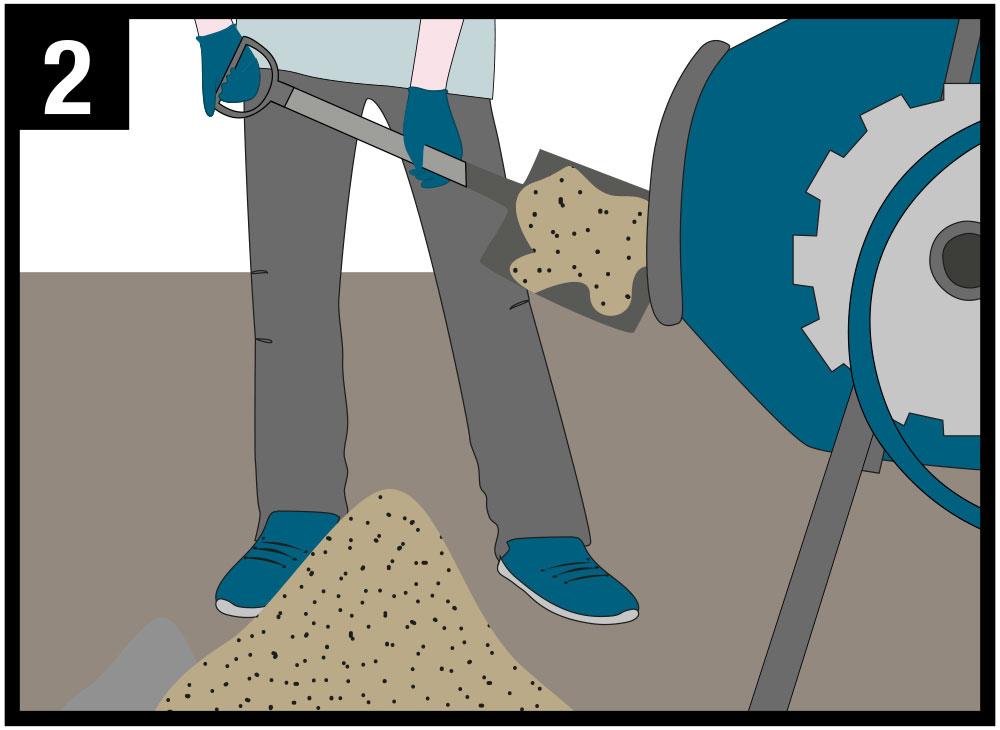

3) Spread the adhesive for sintered stone on the back of the slabs.

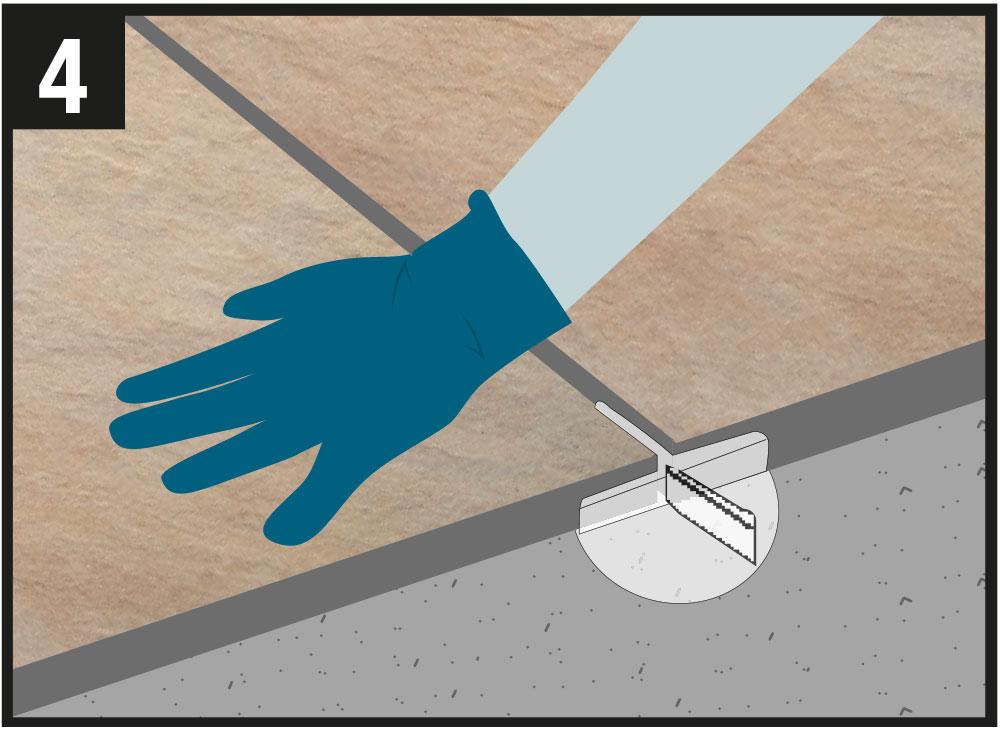

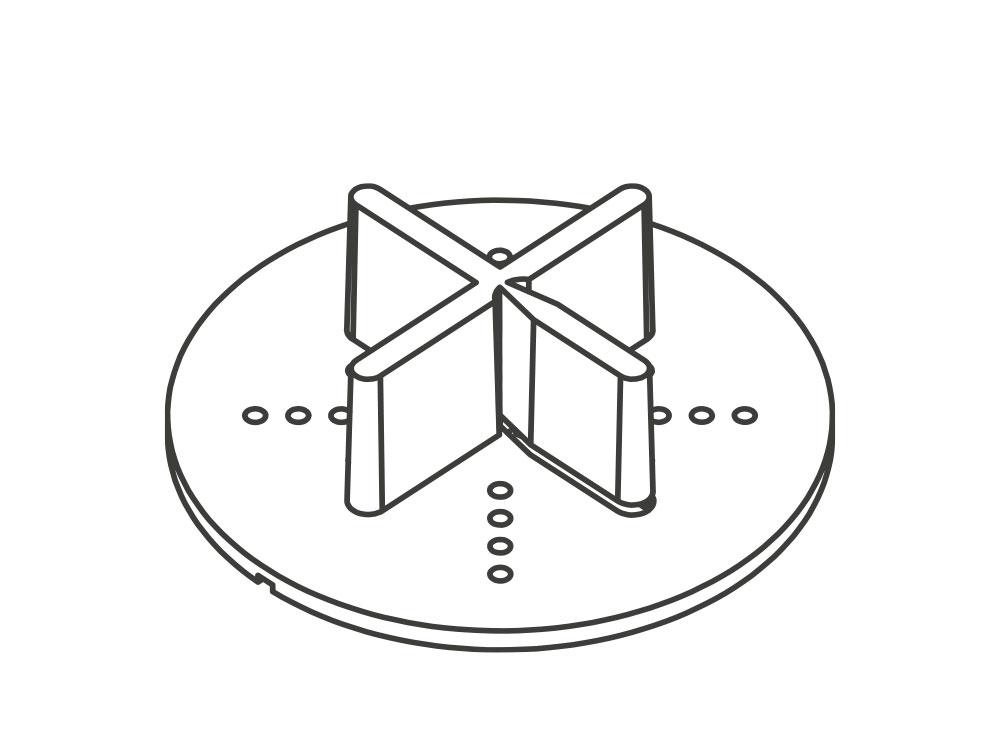

4) Lay the slabs with the aid of the Crocette cross spacers.

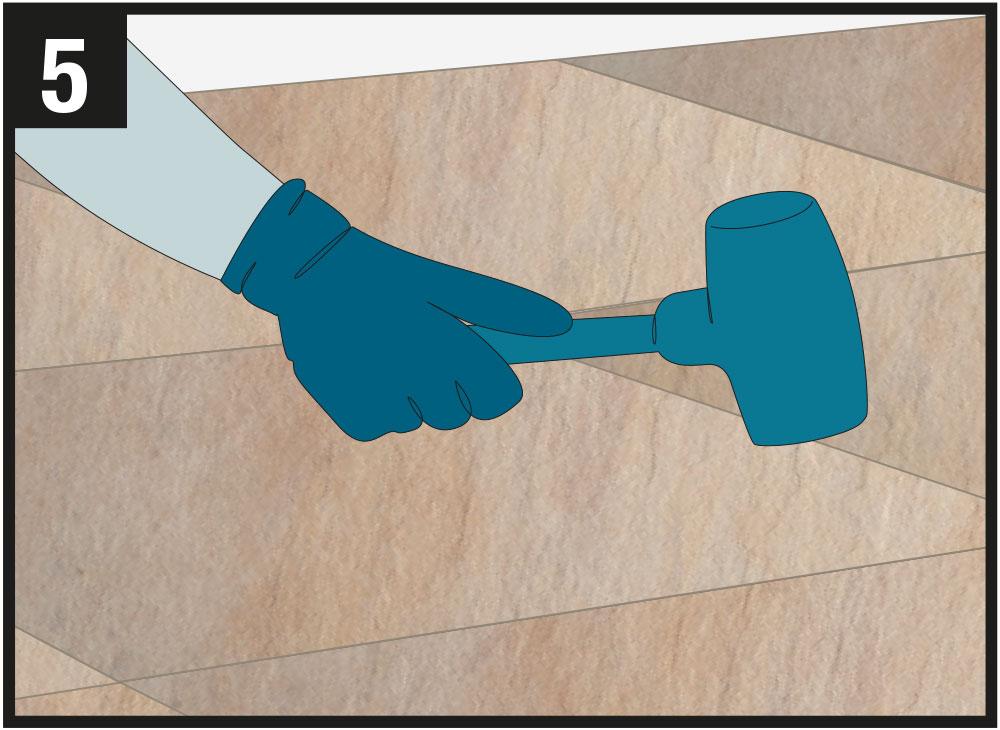

5) Use the rubber mallet to level the slabs.

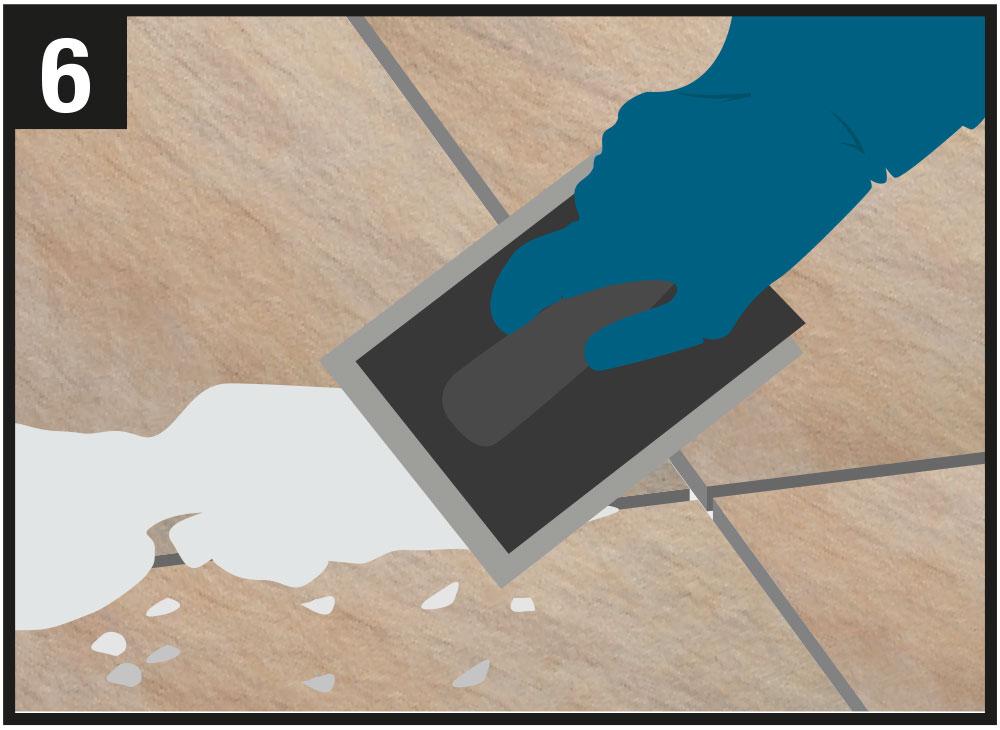

6) Once the laying is complete, proceed with the grouting.

What you need:

Slab

Level

Toothed Spatula

Sand

Cement

Adhesive

Concrete mixer

Rubber mallet

Vibro compactor

Cross spacers

Installation

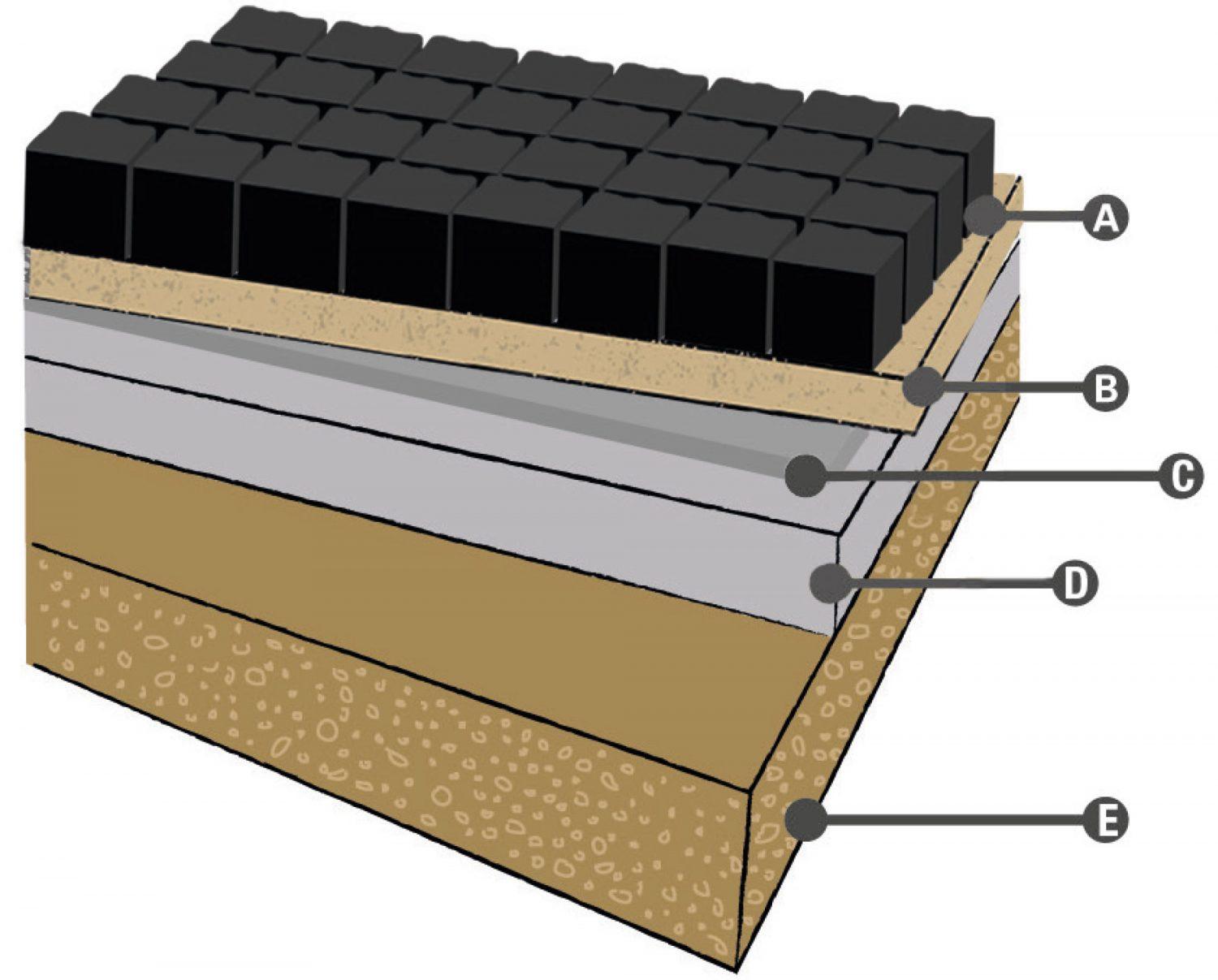

Example of laying on ground of

STONE GRES Pavè

- A) Slab

- B) Mixed cement sand

- C) Screed with electrowelded mesh

- D) Roadbed

- E) Soil

The proposed diagrams and indications are purely indicative of the type of application: please refer to the specific regulations in force in your country in order to lay the floor to the highest technical standards. It is recommended to lay with a 2% slope to avoid water accumulation.

Instructions:

1) On the roadbed, make a screed with an electro-welded net of about 5 cm (2") thickness and wait for its maturation.

2) Prepare the sand mixture in the cement mixer, two parts of cement in weight for every ten parts of sand, cement and water in equal parts.

3) Lay a layer of equal to or more than 3 cm (1.2") of the sand mixture over the matured screed.

4) Lay the cobblestones spacing them with a joint between 5 and 20 mm (0.02"-0.07"), making them adhere well to the cement mixed sand layer.

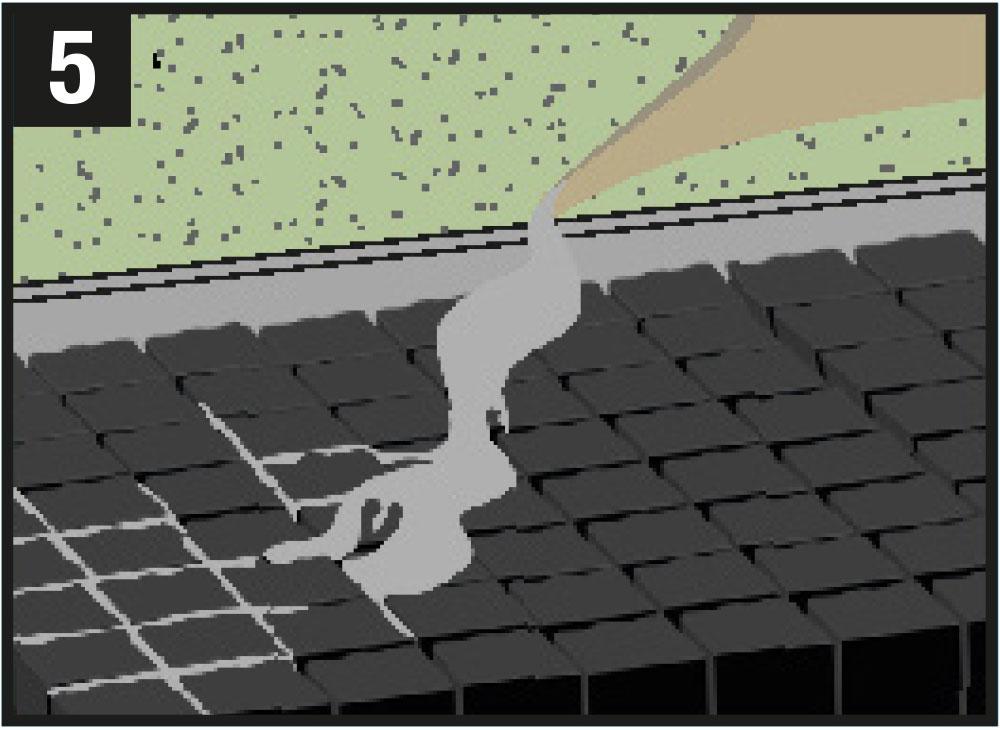

5) Once the laying is completed, the joints can be filled with polymeric sand or cement grout.

What you need:

Pavè

Level

Sand

Cement

Concrete mixer

Rubber mallet